However, integrating reuse or remanufacturing into existing manufacturing operations also brings challenges. One of the main barriers companies face is the potential disruption to their current production flows, which often them from implementing reuse strategies, despite the long-term value they offer.

Implementing reuse in manufacturing

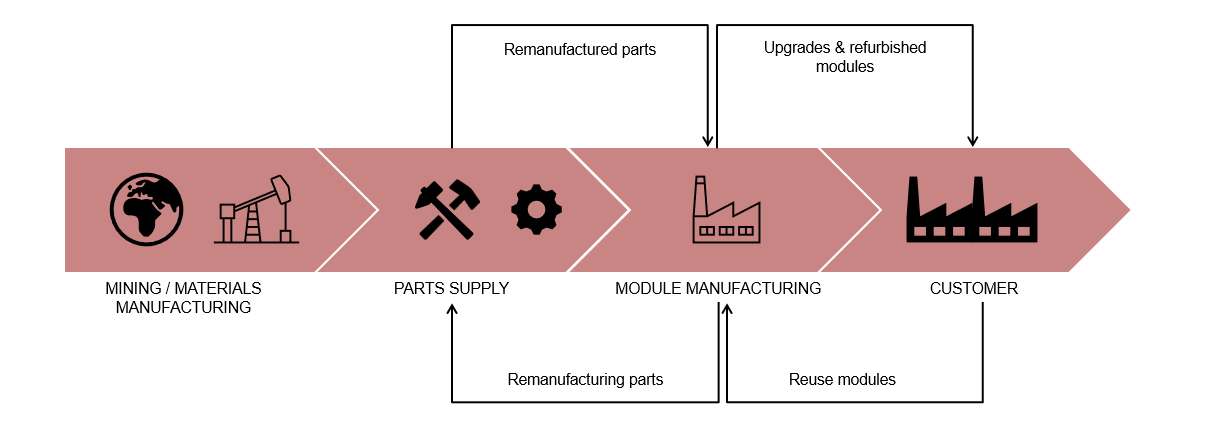

Sustainability, material scarcity and energy consuming manufacturing processes are accelerating the transition from a linear to a circular economy. This shift is not only essential for the environment but also presents a strategic opportunity for cost savings and business resilience. Practices such as reuse , remanufacturing, recycling and refurbishing provide a solution. By reusing materials and components, companies can reduce dependency on scarce resources, cut costs, and contribute to a more sustainable world.

Challenges

Nobleo's approach

This is where Nobleo Manufacturing comes in. Through our specialised engineering services, we support companies in adopting and embedding reuse strategies into their operations, without compromising productivity. Our know how of manufacturing processes allows us to help clients effectively configure essential processes such as ERP system integration, incoming inspection, disassembly, cleaning, and requalification. By doing so, we help turn reuse into a structured and scalable part of everyday manufacturing.

“Our know how of manufacturing processes allows us to help our customers turn reuse into a structured and scalable part of everyday manufacturing.”

Rik Peeters – Industrial engineer – Rik Peeters – Industrial engineer

What does our approach look like

- We guide the analysis and help prioritise high-impact reuse opportunities, tailored to your operations and product architecture.

- We help design and implement reuse loops into your existing operations and configure your ERP systems and workflows accordingly.

- We support the development of supplier strategies and coordinate pilot programs to validate reuse processes in real-world settings.

- We co-create and implement standards for reuse, ensuring control, traceability, and long-term reliability of reuse strategies.

Curious how reuse can contribute to cost savings and sustainability within your organisation? Let’s explore the possibilities together. Contact us today to see how we can support your transition toward a more circular and efficient manufacturing process.

Achieving New Level Manufacturing Together

I’m here to help you find the role that fits your talent and ambition.