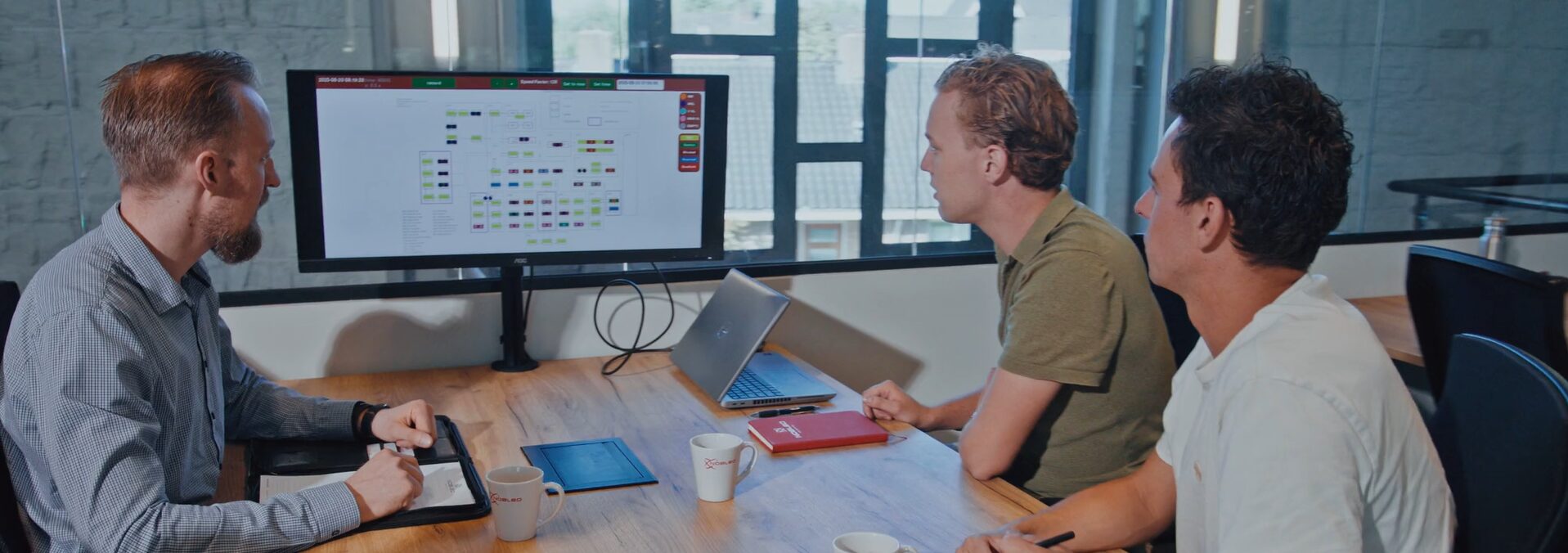

Manufacturing Intelligence

Manufacturing Intelligence forms the basis for giving customers valuable insight into their processes. With expertise in digital twin software, industrial automation solutions, predictive analytics and factory data collection solutions, we help manufacturers grow into next level manufacturing by helping them make informed decisions to optimise production, reduce risk and accelerate digital transformation.

Optimisation

We help customers achieve faster, more accurate planning, resulting in increased efficiency and reduced costs.

Digital roadmap partner

We guide customers through every stage of digitalisation using digital twin technology.

Simulation & digitalisation

Experts in modelling discrete manufacturing networks and creating valuable and reliable business insights.